Turbine

OUR PARTNER

HANGZHOU CHINEN STEAM TURBINE POWER CO., LTD. (HCTC)

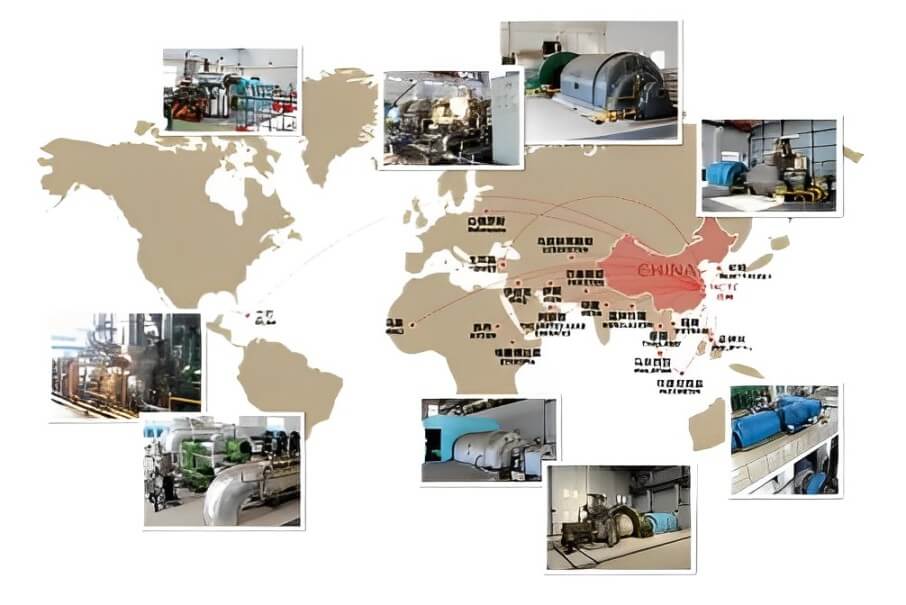

Hangzhou Chinen Steam Turbine Power Co., Ltd. (HCTC), founded on December 28th 2003.HCTC has a main workshop of more than 25,000 square meters, the production capacity of steam turbine was 350 sets per year, the largest steam turbine was 75MW,and the yearly output value was over RMB 1.5 billion. Since the establishment, HCTC has produced about 1,500 sets of steam turbines, succeeded in developing of 12MW~75MW condensing steam turbine and extraction-condensing steam turbine used indry quenching steel industry with high temperature &pressure, 6.7MW~40MWcondensing turbine used for driving high blast furnace, induction-condensing steam turbine and condensing steam turbine below 35MW used for saturated steam power generation plant, condensing and backpressure type turbine used for refining, chemical industries for driving highspeed fans and compressors, condensing steam turbine for driving feed water pump of boiler for 135MW, 20MW, 3MMW, 600MW power plant,3MW~36MW steam turbine used for heat recovery in cement industry and etc., which accounts for a total of more than 80 series with 300 types. In order to provide quality service and satisfy each customer in time, HCTC had set up 8 technology service branch companies in China.

PRODUCTS CATALOG

Mechanical Driven Turbine For driving compressors, fans, pumps reciprocating machine and etc

|

Type |

Design Condition |

|||||

| Inlet Pressure | Inlet Tempera Ture | Extract Ion | Exhaust Range | Power Range | Speed Range | |

| Unit | MPa(a) | ฺฺฺฺ°C | MPa(a) | MPa(a) | KW | r/min |

| Condensing | 0.12~10.5 | 105~540 | / | 0.007~0.025 | 100~60000 | 3000~14200 |

| Extraction/Condensing | 1.0~10.5 | 180~540 | 0.2~5.0 | 0.007~0.025 | 1000~60000 | 3000~14200 |

| Back pressure | 0.5~14 | 152~540 | / | 0.12~6.5 | 100~60000 | 3000~15000 |

| Extraction/Back pressure | 1.0~14 | 180~540 | 0.5~6.5 | 0.12~6.5 | 500~60000 | 3000~15000 |

|

Type |

Design Condition |

|||||

| Inlet Pressure | Inlet Tempera Ture | Extract Ion | Exhaust Range | Power Range | Speed Range | |

| Unit | MPa(a) | ฺฺฺฺ°C | MPa(a) | MPa(a) | KW | r/min |

| Condensing | 0.12~10.5 | 105~540 | / | 0.007~0.025 | 100~60000 | 3000~14200 |

| Extraction/Condensing | 1.0~10.5 | 180~540 | 0.2~5.0 | 0.007~0.025 | 1000~60000 | 3000~14200 |

| Back pressure | 0.5~14 | 152~540 | / | 0.12~6.5 | 100~60000 | 3000~15000 |

| Extraction/Back pressure | 1.0~14 | 180~540 | 0.5~6.5 | 0.12~6.5 | 500~60000 | 3000~15000 |

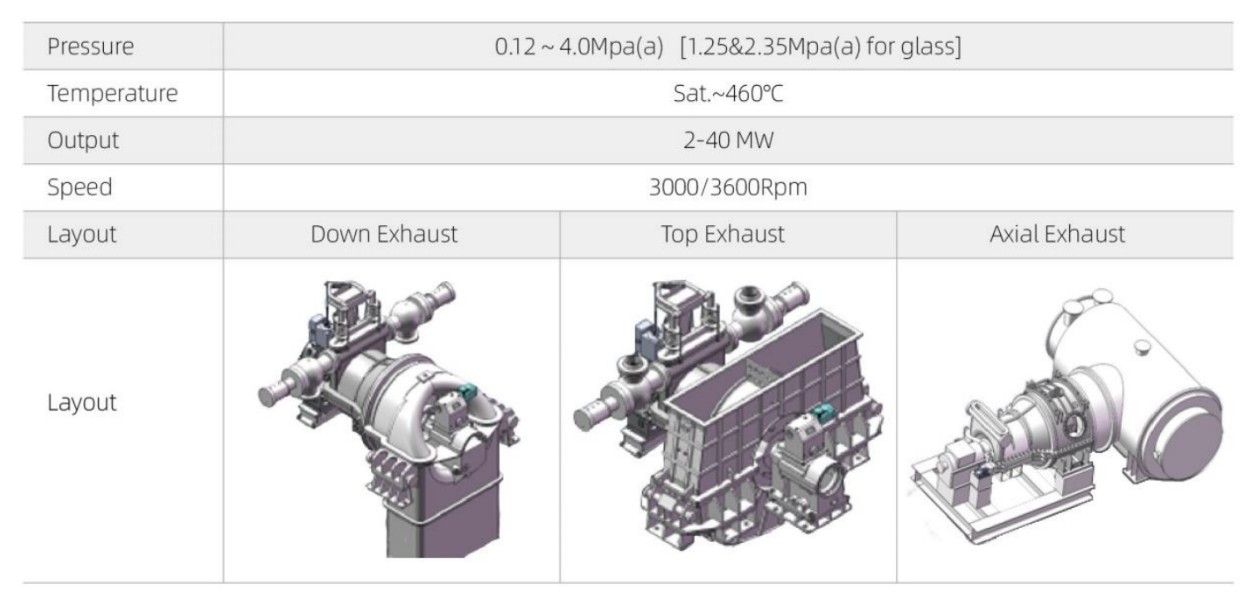

Power Generation Turbine For driving generators

| Power | Speed | Layout | Classification | ||||||

| Down Exhaust | Condensing | Back pressure | Extraction /injection | ||||||

| KW | r/min | Top Exhaust | Inlet Pressure | Inlet Temperature | Exhaust | Inlet Pressure | Inlet Temperature | Exhaust | |

| Axial Exhaust | Mpa(a) | °C | Mpa(a) | Mpa(a) | °C | Mpa(a) | |||

| 0.5~2500 | 9000/11000 | D/T/A | 0.17~6.4 | sat.-470 | 0.008-0.30 | 2.0-8.83 | sat.-470 | 0.25-4.0 | E/I |

| 3000 | 3000/3600/9000/11000 | D/T/A | 0.17~6.4 | sat.470 | 0.005~0.30 | 2.0~13.2 | sat.-535 | 0.25~4.0 | E/I |

| 4500 | 3000/3600/9000/11000 | D/T/A | 0.6~8.83 | sat.-535 | 0.005~0.30 | 2.0~13.2 | sat.-535 | 0.25~4.0 | E/I |

| 6000 | 3000/3600/9000/11000 | D/T/A | 0.6~8.83 | sat.-535 | 0.005~0.30 | 2.0~13.2 | sat.-535 | 0.25-4.0 | E/I |

| 7500 | 3000/3600/9000/11000 | D/T/A | 0.6~8.83 | sat.-535 | 0.005~0.30 | 2.0~13.2 | sat-535 | 0.25~4.0 | E/I |

| 9000 | 3000/3600/9000/11000 | D/T/A | 0.6~8.83 | sat.555 | 0.005-0.30 | 3.43~13.2 | sat.535 | 0.25~4.0 | E/I |

| 12000 | 3000/3600/9000/11000 | D/T/A | 0.6~8.83 | sat.-535 | 0.005~0.30 | 3.43~13.2 | sat.535 | 0.25~4.0 | E/I |

| 15000 | 3000/3600/6700/8500 | D/T/A | 0.6~8.83 | sat-535 | 0.005-0.30 | 3.43~13.2 | sat~535 | 0.25~4.0 | E/I |

| 18000 | 3000/3600/6700 | D/T | 0.6~8.83 | sat.-535 | 0.005-0.30 | 3.43~13.2 | sat.-535 | 0.25-4.0 | E/I |

| 20000 | 3000/3600/6700 | D/T | 0.6~8.83 | sat.-535 | 0.005~0.30 | 3.43~13.2 | sat.-535 | 0.25~4.0 | E/I |

| 25000 | 3000/3600/6700 | D/T | 0.6~8.83 | sat.-535 | 0.005-0.30 | 3.43~13.2 | sat.-535 | 0.25~4.0 | E/I |

| 30000 | 3000/3600/6700 | D/T | 0.6~8.83 | sat.535 | 0.005~0.30 | 3.43~13.2 | sat-535 | 0.25~4.0 | E/I |

| 35000 | 3000/3600 | D/T | 0.6~13.2 | sat-535 | 0.005~0.30 | 3.43~13.2 | sat-535 | 0.25-4.0 | E/I |

| 40000 | 3000/3600 | D | 1.0~13.2 | sat.-535 | 0.005~0.30 | 3.43~13.2 | sat-535 | 0.25-4.0 | E/I |

| 45000 | 3000/3600 | D | 1.0~13.2 | sat-535 | 0.005~0.30 | 3.43~13.2 | sat.-535 | 0.25-4.0 | E/I |

| 50000 | 3000/3600 | D | 1.0~13.2 | sat-535 | 0.005-0.30 | 3.43~13.2 | sat-535 | 0.25~4.0 | E/I |

| 60000 | 3000/3600 | D | 3.43-13.2 | sat-535 | 0.005-0.30 | 3.43~13.2 | sat.-535 | 0.25-4.0 | E/I |

| 75000 | 3000/3600 | D | 3.43~13.2 | sat-535 | 0.005-0.30 | 3.43~13.2 | sat.535 | 0.25~4.0 | E/I |

Centrifugal Compressor

| Generation | H | V | C |

| Type | horizontal split | vertical split | multi-rotors |

| Casing | welded | forged | geared |

| Medium | varloUs | various | Air, N₂, Vapor |

| Exhaust pressure | <4.0MPa (a) | >4. OMPa (a) | pressure ratio<20 |

| Speed | <15000 rpm | <15000 rpm | <40000 rpm |

| Power | <25000 kw | <20000 kw | <10000 kw |

| Generation | H | V | C |

| Type | horizontal split | vertical split | multi-rotors |

| Casing | welded | forged | geared |

| Medium | varloUs | various | Air, N₂, Vapor |

| Exhaust pressure | <4.0MPa (a) | >4. OMPa (a) | pressure ratio<20 |

| Speed | <15000 rpm | <15000 rpm | <40000 rpm |

| Power | <25000 kw | <20000 kw | <10000 kw |

Generator Classification

| Code | Power | Voltage | Power Factor | Speed | Efficient | Total Weight | Rotational Inertia | center Distance | Center Height | |

| PN | PA | UN | Cos | nN | n | G | GD2 | mm | mm | |

| KVA | KW | KV | r/min | % | kg | t-m2 | ||||

| OF-3 | 3750 | 3000 | 6.3/10.5 | 0.8 | 3000/3600 | 96.3 | 14350 | 0.204 | 3370 | 500 |

| QF-4.5 | 5625 | 4500 | 6.3/10.5 | 0.8 | 3000/3600 | 96 | 20420 | 0.84 | 3770 | 630 |

| QF-6 | 7500 | 6000 | 6.3/10.5 | 0.8 | 3000/3600 | 96.4 | 22720 | 0.99 | 4120 | 630 |

| QF-7.5 | 9375 | 7500 | 6.3/10.5 | 0.8 | 3000/3600 | 96.9 | 23400 | 0.99 | 4120 | 630 |

| QF-9 | 11250 | 9000 | 6.3/10.5 | 0.8 | 3000/3600 | 97 | 30000 | 1.6 | 4040 | 630 |

| QF-12 | 15000 | 12000 | 6.3/10.5 | 0.8 | 3000/3600 | 97.3 | 33400 | 1.8 | 4310 | 630 |

| QF-15 | 18750 | 15000 | 6.3/10.5 | 0.8 | 3000/3600 | 97.4 | 40500 | 2.06 | 4660 | 630 |

| QF-18 | 22500 | 18000 | 6.3/10.5 | 0.8 | 3000/3600 | 97.4 | 53300 | 3.5 | 4920 | 750 |

| QF-20 | 25000 | 20000 | 6.3/10.5 | 0.8 | 3000/3600 | 97.5 | 54250 | 3.5 | 4920 | 750 |

| QF-25 | 31250 | 25000 | 6.3/10.5 | 0.8 | 3000/3600 | 97.7 | 59800 | 3.9 | 5340 | 750 |

| QF-30 | 37500 | 30000 | 6.3/10.5 | 0.8 | 3000/3600 | 97.6 | 66400 | 3.9 | 5760 | 750 |

| QF-35 | 43750 | 35000 | 6.3/10.5 | 0.8 | 3000/3600 | 97.8 | 71600 | 3.9 | 5760 | 750 |

| QF-40 | 50000 | 40000 | 6.3/10.5 | 0.8 | 3000/3600 | 97.9 | 78500 | 4.3 | 5760 | 750 |

| QF-45 | 56250 | 45000 | 6.3/10.5 | 0.8 | 3000/3600 | 98 | 78500 | 7 | 6000 | 750 |

| QF-50 | 62500 | 50000 | 6.3/10.5 | 0.8 | 3000/3600 | 98.1 | 113500 | 8.3 | 6340 | 750 |

| QF-60 | 75000 | 60000 | 6.3/10.5 | 0.8 | 3000/3600 | 98.2 | 117000 | 8.3 | 6340 | 750 |

| QF-70 | 87500 | 70000 | 6.3/10.5 | 0.8 | 3000/3600 | 98.5 | 126300 | 8.5 | 6300 | 800 |

Compressor Type

Horizontally Split Compressor

Vertically Split Compressor

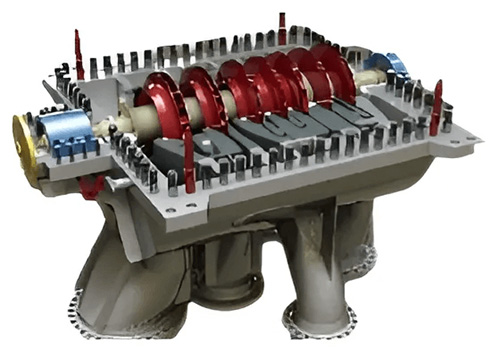

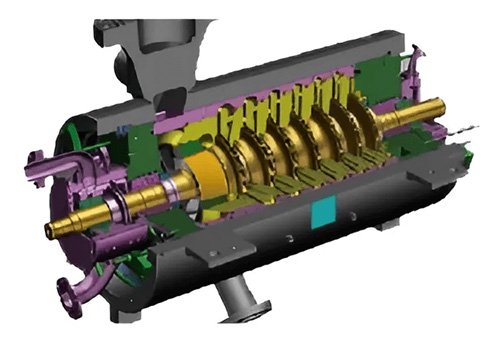

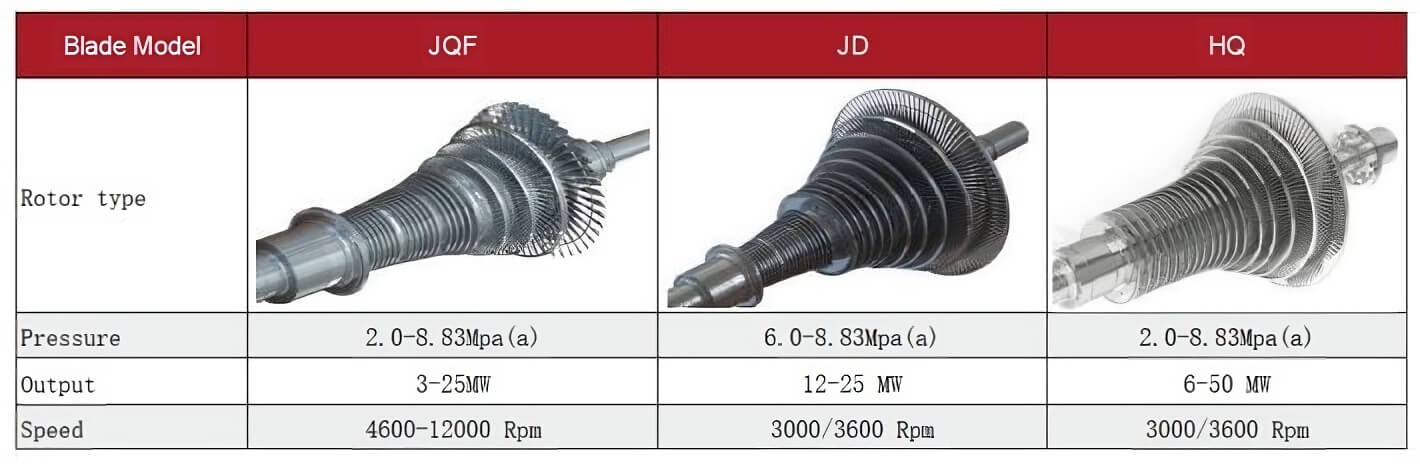

Characteristic of Core Turbine Model

- High efficiency model

- ≤3MW

| Туре | Condensing | Back pressure |

| Pressure | 2. 0 – 5. 0Mpa (a) | 2.0 – 5. 0Mpa (a) |

| Output | ≤3 MW | ≤ 3 MW |

| Speed | 8000 – 12000 Rpm | 8000 – 12000 Rpm |

| Arrangement | Single floor, no need to open casing on site installation | Single floor, no need to open casing on site installation |

| Туре | Condensing | Back pressure |

| Pressure | 2. 0 – 5. 0Mpa (a) | 2.0 – 5. 0Mpa (a) |

| Output | ≤3 MW | ≤3 MW |

| Speed | 8000 – 12000 Rpm | 8000 – 12000 Rpm |

| Arrangement | Single floor, no need to open casing on site installation | Single floor, no need to open casing on site installation |

- High market share-low pressure and saturated inlet steam